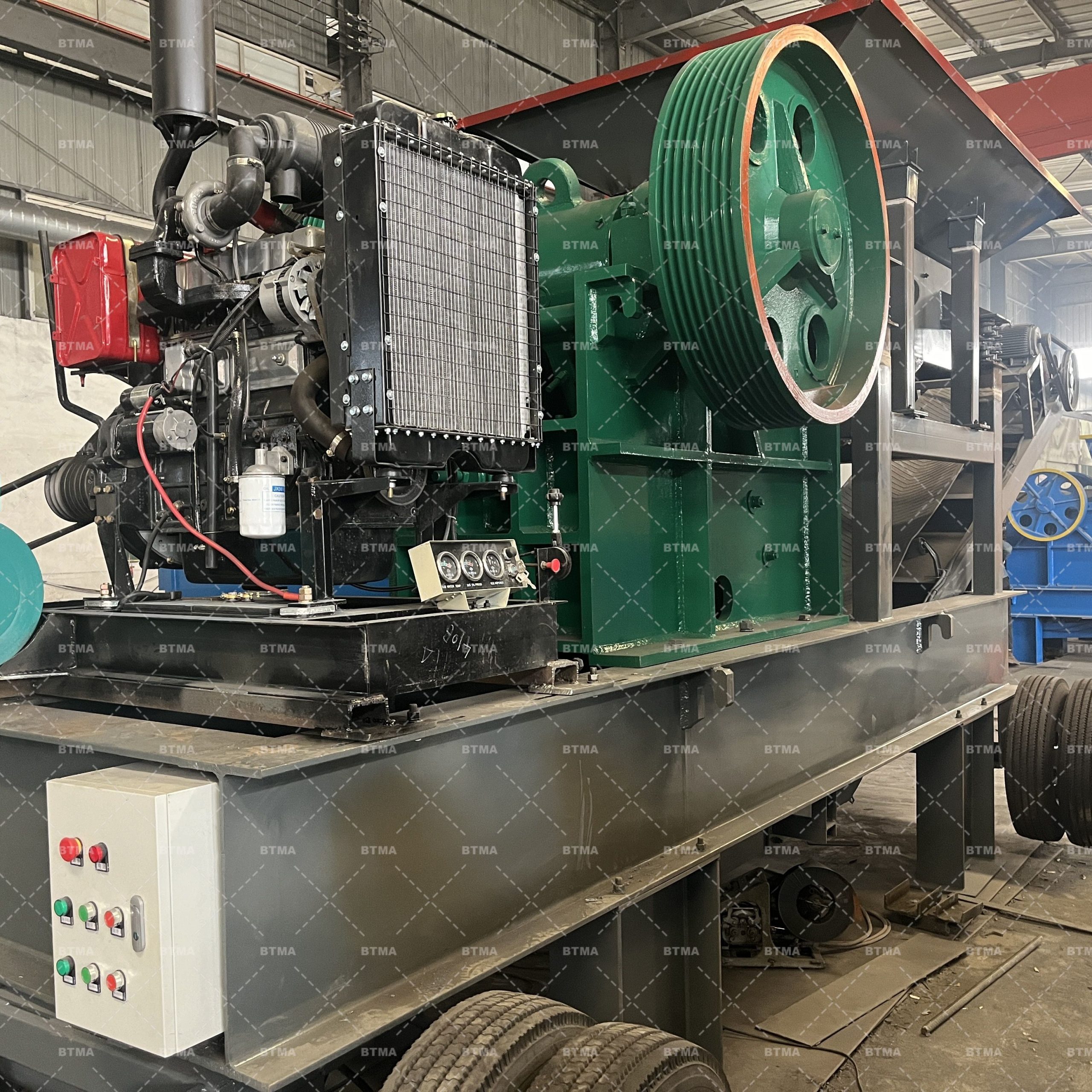

Mobile Jaw Crusher Plant: Efficient Crushing Anywhere

The Mobile Jaw Crusher Plant is a powerful, portable solution for on-site crushing and screening. Perfect for mining, construction, and recycling, it combines high-performance crushing with mobility, allowing you to process materials directly at the job site—saving time and costs.

Why Choose the Mobile Jaw Crusher Plant?

- Portable and Flexible: Easily move between job sites, saving on transportation costs and setup time.

- Efficient Crushing: High-capacity jaw crusher handles tough materials like rock, concrete, and asphalt with ease.

- Integrated Screening: Built-in vibrating screen sorts materials into different sizes, optimizing the crushing process.

- Cost-Effective: Reduced need for multiple machines, cutting operational and maintenance costs.

- Eco-Friendly: Lower dust, noise, and energy consumption for sustainable operation.

Key Benefits:

- Increased Productivity: Continuous crushing and screening ensures fast material processing and reduced downtime.

- Versatile Applications: Ideal for mining, road construction, recycling, and demolition projects.

- Lower Operating Costs: Save on fuel, transport, and equipment maintenance with an all-in-one mobile solution.

How It Works:

Material is fed into the jaw crusher for primary crushing, then screened for size, and conveyed to stockpiles or further processing. It’s a simple, efficient solution that reduces material handling and boosts productivity.

Jaw crusher specific specifications

| Model | Feed port size (mm) | Maximum feed size (mm) | Adjustable size of discharge opening (mm) | Capacity(t/h) | Motor power (kw) | weight(t) |

| PE150x250 | 150×250 | 125 | 10-40 | 1-5 | 5.5 | 0.8 |

| PE200x300 | 200×300 | 180 | 15-50 | 5-10 | 7.5 | 1.2 |

| PE220x350 | 220×350 | 180 | 18-70 | 8-15 | 11 | 1.5 |

| PE250x400 | 250×400 | 210 | 20-60 | 5-20 | 15 | 2.8 |

| PE300x500 | 300×500 | 280 | 25-80 | 20-40 | 18.5 | 3.5 |

| PE400x600 | 400×600 | 340 | 40-100 | 16-60 | 30 | 7 |

| PE500x750 | 500×750 | 425 | 50-100 | 40-110 | 55 | 12 |

| PE600x900 | 600×900 | 500 | 65-160 | 50-180 | 75 | 17 |

| PE750x1060 | 750×1060 | 630 | 80-140 | 110-320 | 110 | 29 |

| PEX100x600 | 100×600 | 80 | 10-30 | 5-15 | 7.5 | 2.8 |

| PEX150x750 | 150×750 | 120 | 18-48 | 8-25 | 15 | 3.8 |

| PEX250x750 | 250×750 | 210 | 25-60 | 13-35 | 22 | 5.5 |

| PEX250x1000 | 250×1000 | 210 | 25-60 | 16-52 | 30 | 7 |

| PEX250x1200 | 250×1200 | 210 | 25-60 | 20-61 | 37 | 9.7 |

| PEX300x1300 | 300×1300 | 250 | 20-90 | 16-105 | 55 | 15.6 |